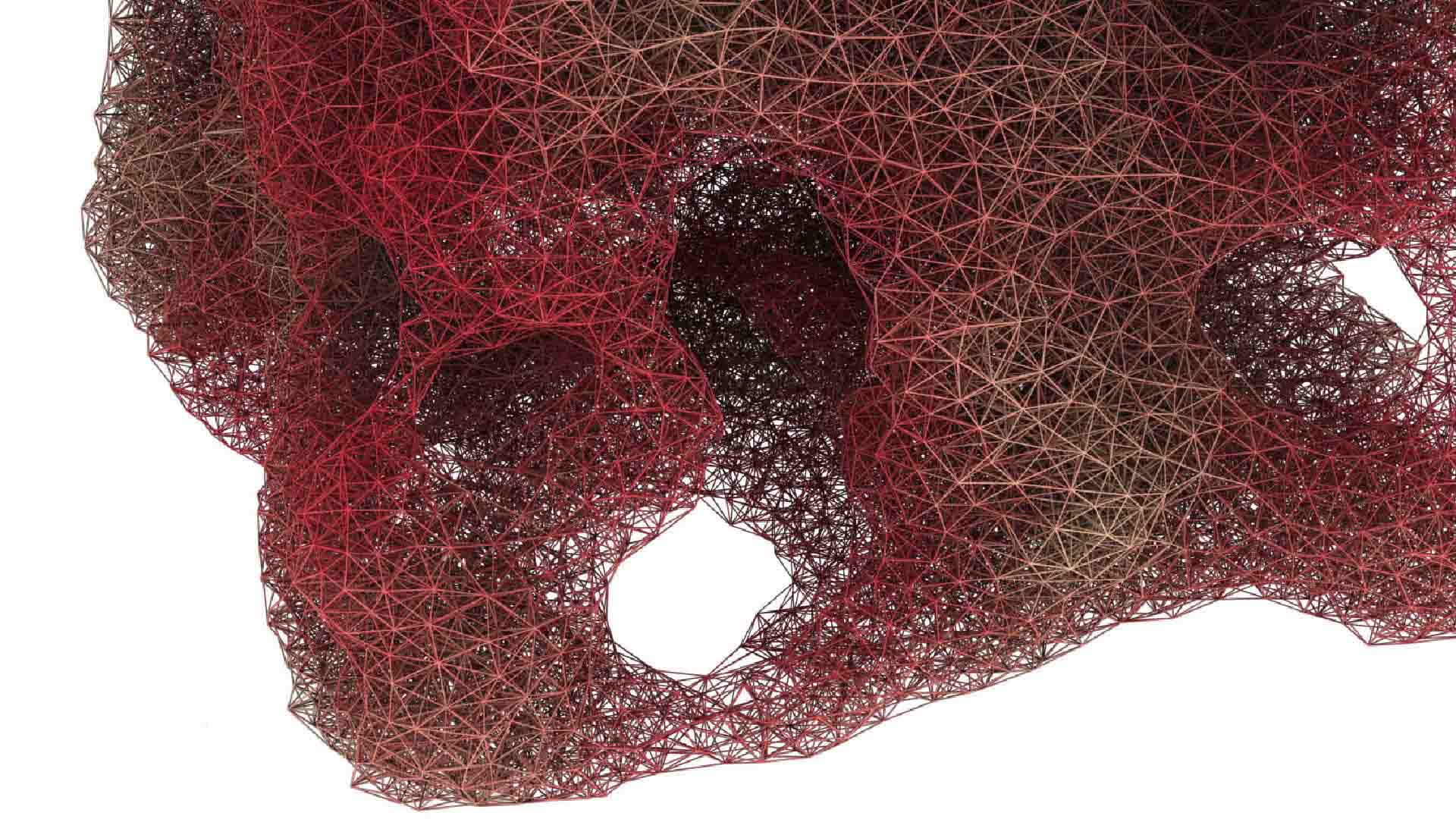

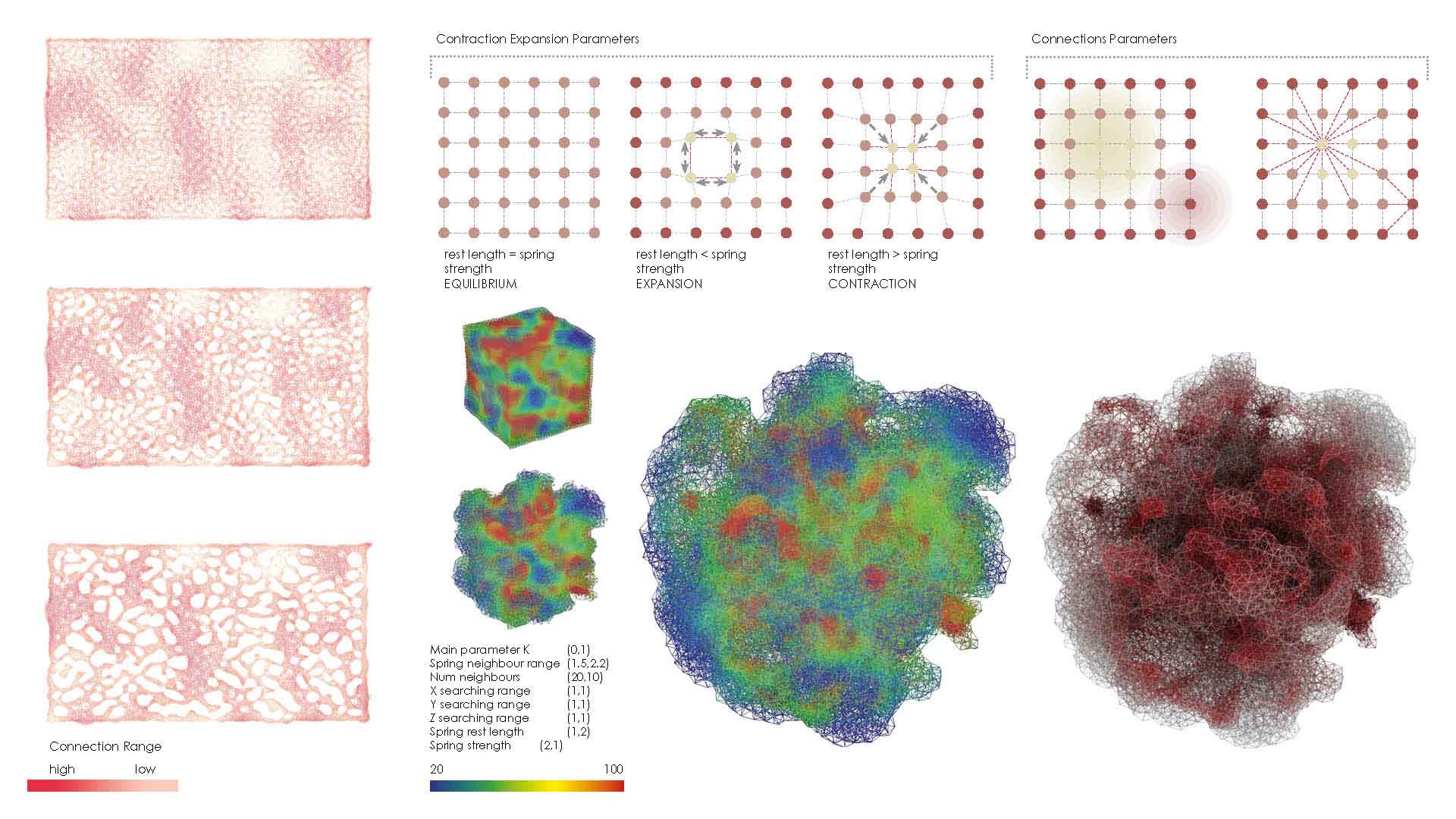

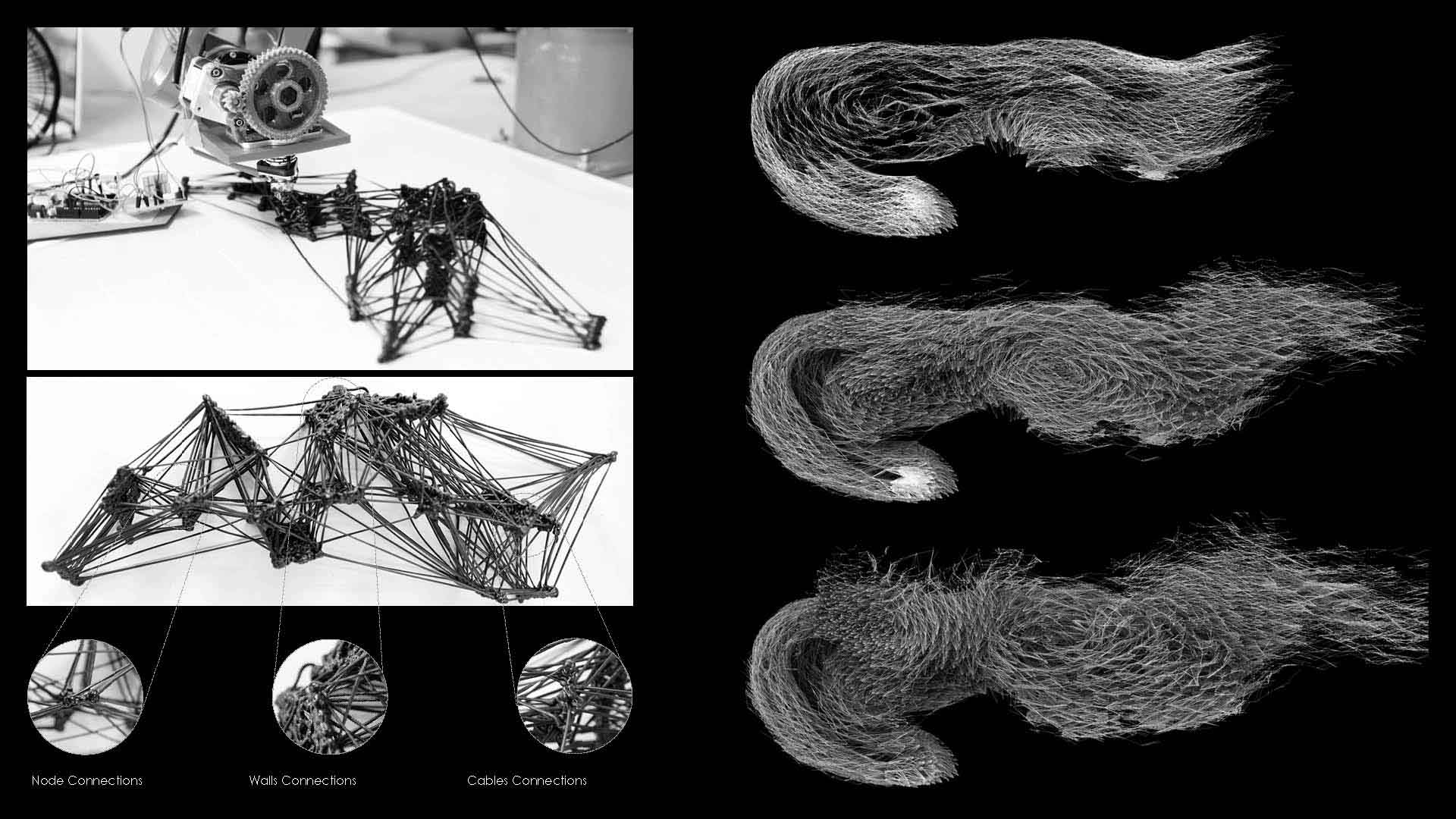

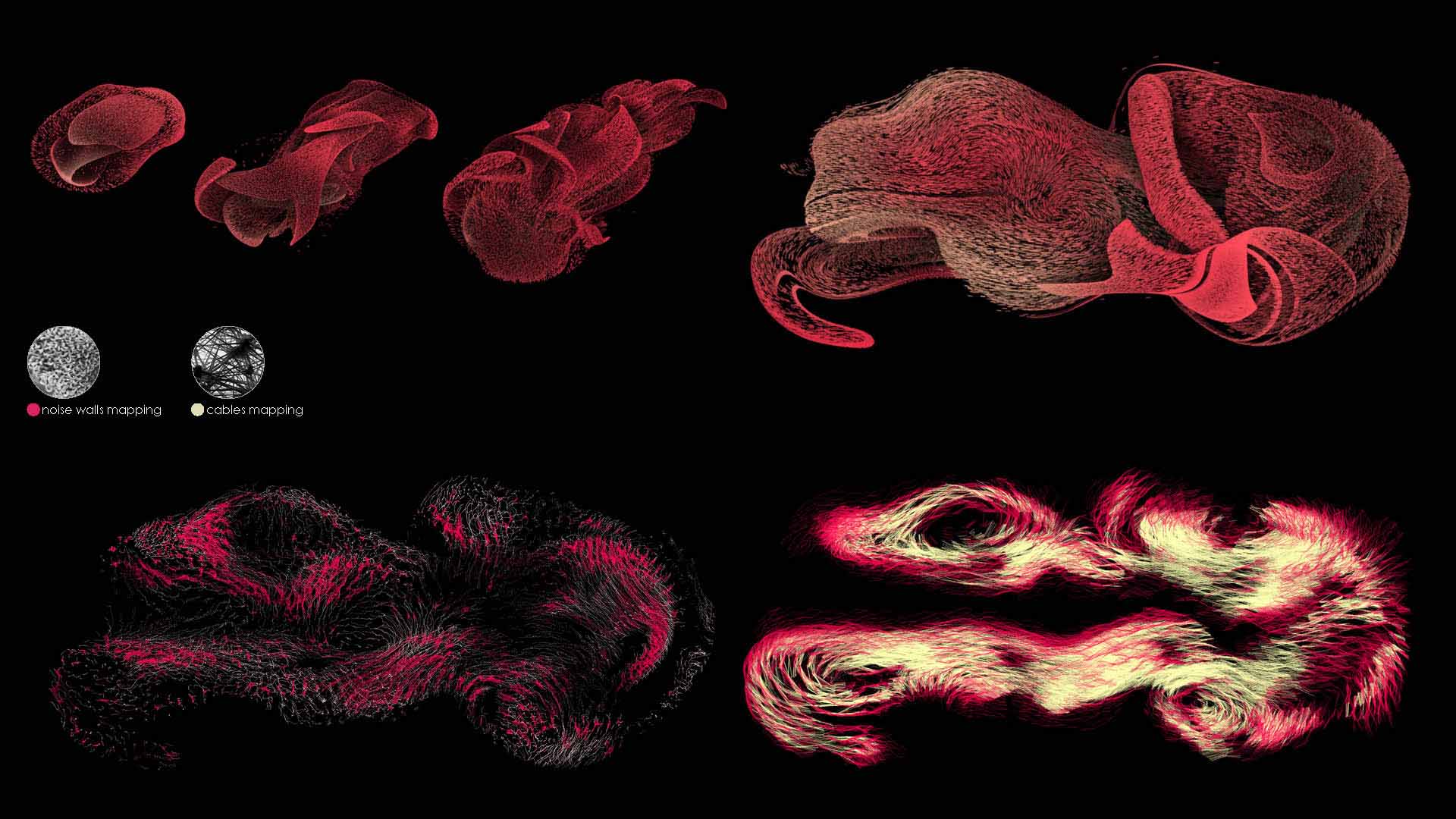

Rheobotics research investigated substances that change state in response to external inputs across different liquid states. The focus was on complex materials with intricate rheological behavior, microstructure geometry, and multiple phases. The research centered on studying viscosity, which measures a fluid’s resistance to gradual deformation due to shear stress. Simulations relied on spring logic to explore the complex microstructure of these liquids, creating emergent formations in response to structural data inputs. Material extrusion was emphasized, offering anti-gravity morphologies without the need for frameworks. An extrusion tool was developed for an ABB robotic arm, enabling a wide range of injection angles, large-scale prototyping, and high precision.

Year | 2014

Location | London

University | Bartlett School of Architecture UCL

Course | Master of Architecture Thesis

Tutor | A. Andrasek

Team | F. Silvi, S. Xiao, T. Guzman