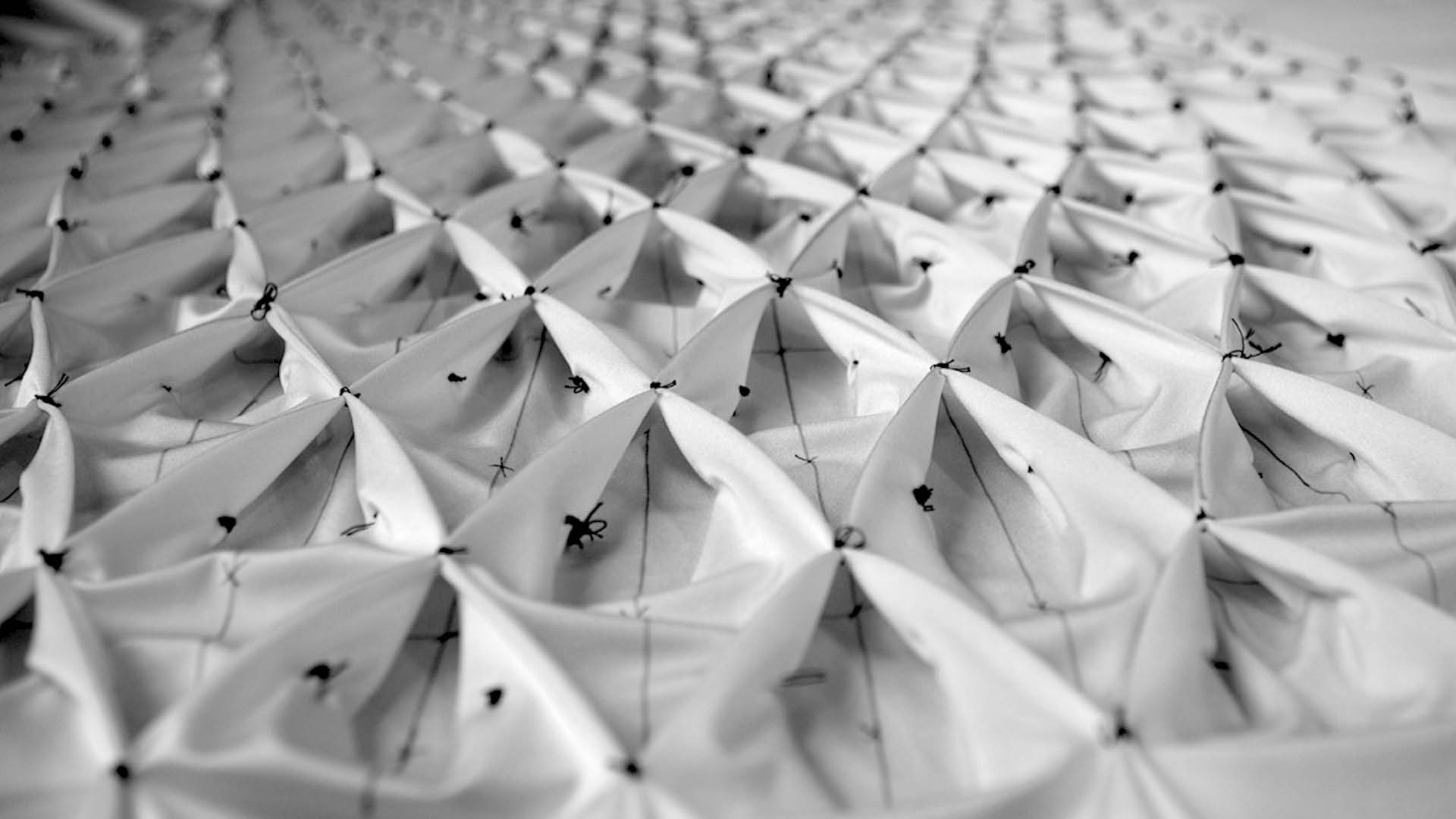

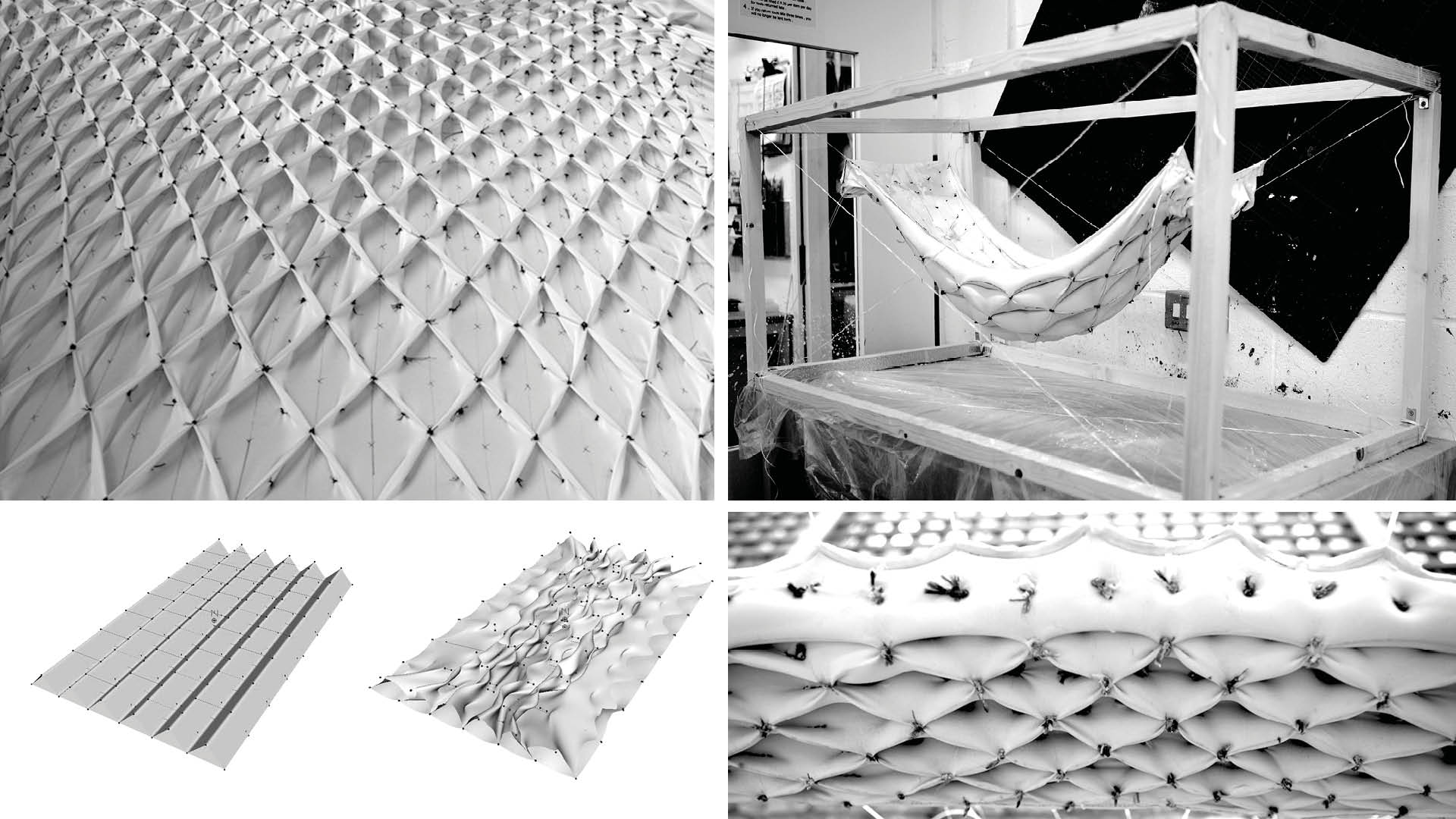

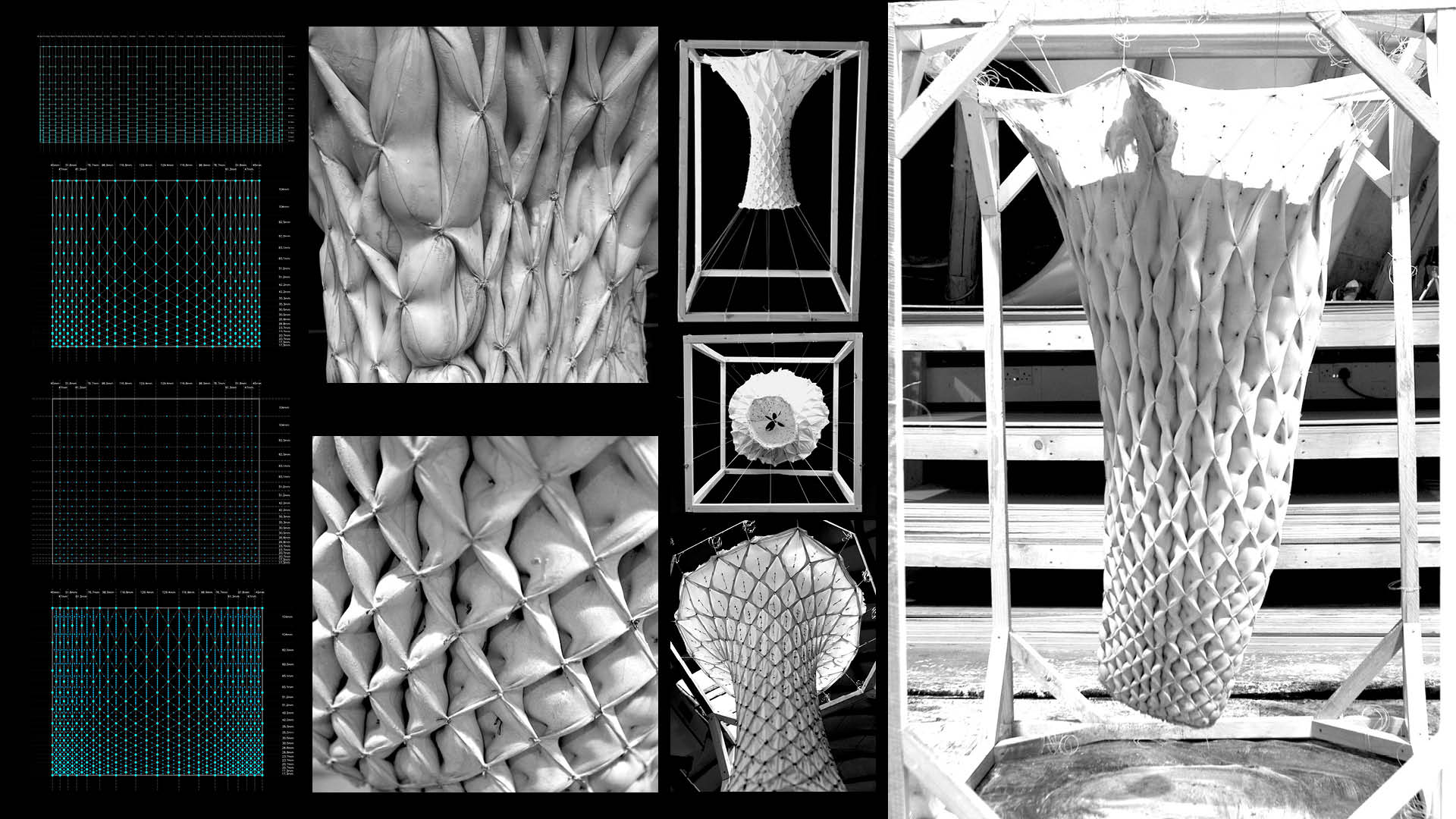

Control By Pattern research examines the use of patterns to control the distribution of material in structural elements like beams and columns. Experiments were conducted to understand how stitching lines could influence the deformation of a beam during casting. The design involves controlling plaster flow within a Lycra membrane. The pattern guides plaster flow, reinforcing the shape, and reducing beam weight. Control points are distributed in a parabolic pattern aligned with the bending moment diagram of a horizontally loaded beam. For vertical casting, control points are positioned according to the movement of the pressure curve to counteract gravity’s effects on column deformation.

Year | 2014

Location | London

University | Architectural Association AA

Course | Master of Architecture Thesis

Tutor | T. Spyropoulos

Team | M. Santi, S. Aburas